About Us

ABOUT US

We spent two years designing the SwivelJet line and getting it just right. Here's how we did it.

After working closely with and listening to CNC operators who grind and machine for a living, it was clear: Most were unhappy with the current coolant lines they used.

Our first attempt at the SwivelJet line used a hose, fittings and a copper rod. It was flexible, held its position and had a good stream of coolant, but it could not be shortened or lengthened easily.

The next generation of brass connectors was flexible. It could easily be changed to a different length quickly and had a good coolant stream. However, it could not be turned far enough for many applications, as in fluting carbide and HSS tools. And when the line was tightened into position, it couldn't be repositioned very easily. So, we went back to work.

THE FINAL RESULT

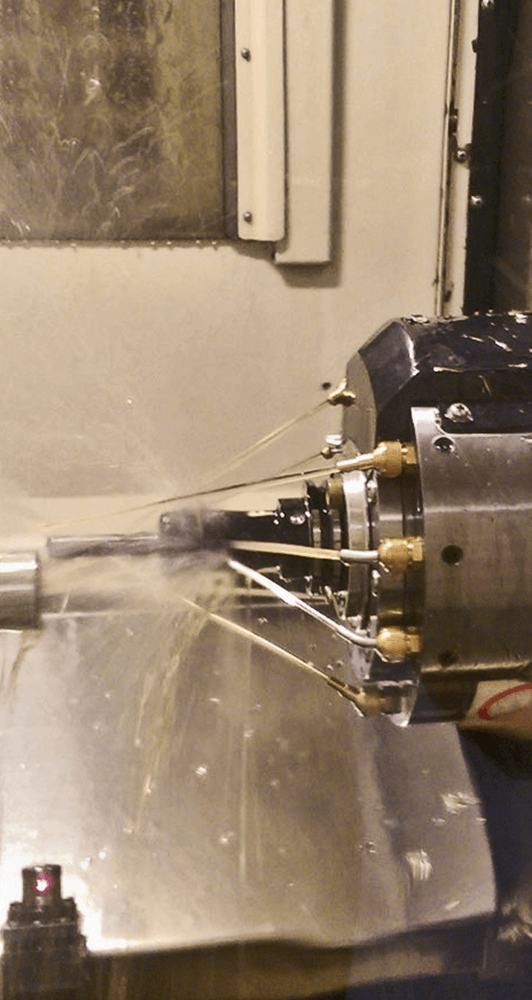

After many design changes, prototypes and testing, the SwivelJet line was complete. It was easy to install, position and change length - and it had an excellent coolant jet.

One of the goals that we accomplished was to incorporate coherent jet technology into the coolant jet coming out of the line. In doing so, the stream of coolant leaving the nozzle reduces the cycle time, wheel loading, heat in grinding zone, and more.

HAVE ANY QUESTIONS?