SHOP BY PRODUCT LINES

Select the product to fit your needs.

SW1 - 3/8" Line

SW2 - 1/4" Line

Specialty Kits

SHOP BY NOZZLE TYPE

Select the nozzle to fit your needs.

Bullet

Flat/Straight

Flutemaster

Gearmaster

Power

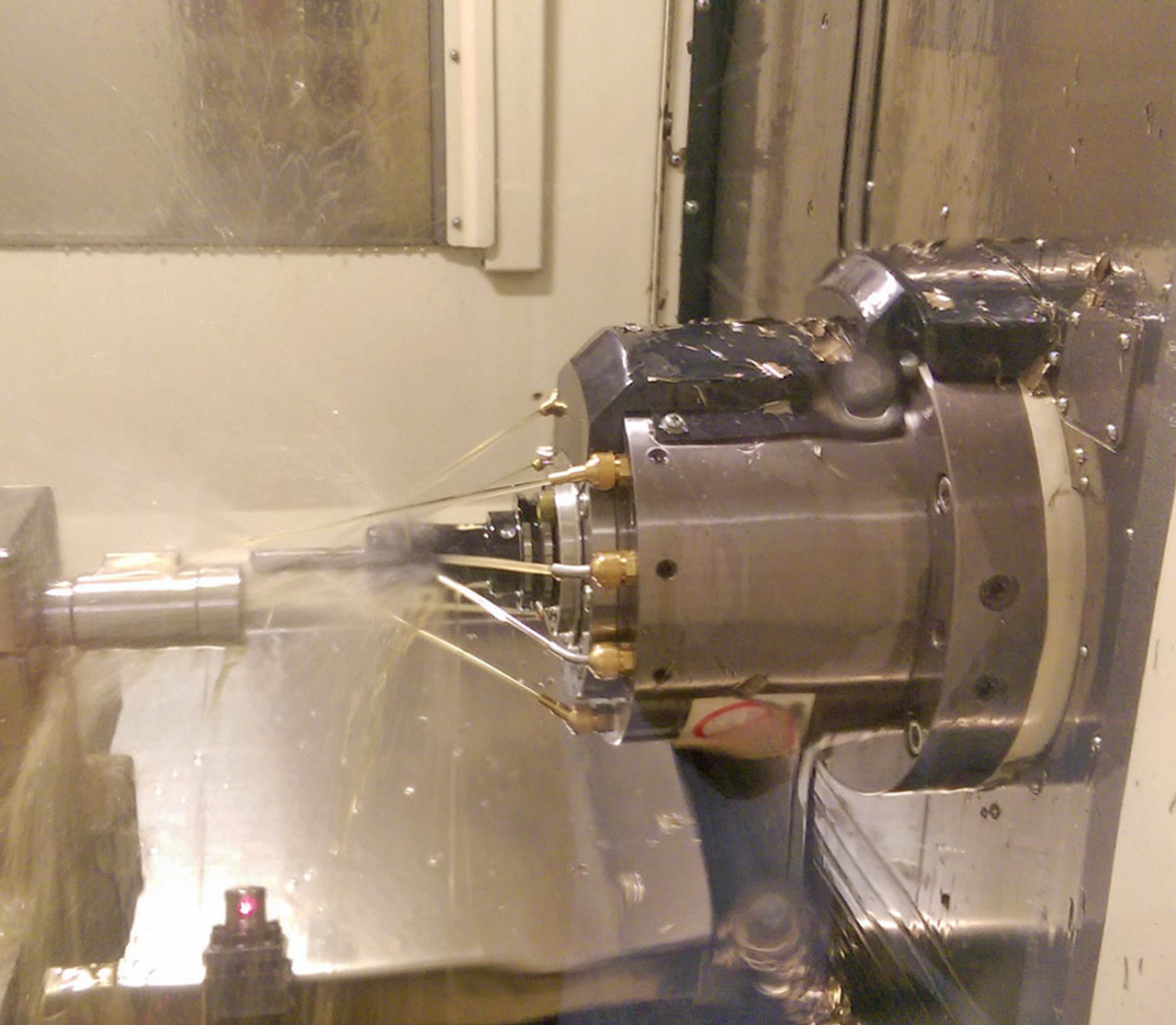

CNC MACHINING

COOLANT NOZZLES

SwivelJet was designed to give you a better choice. It is designed to deliver a strong, cohesive jet of coolant to the grinding or machining area. It is designed to be flexible while rigid at the same time. And it is designed to reduce production costs and increase profits.

WHY SWIVELJET?

SwivelJet was designed to give you a better coolant nozzle line choice. It is designed to deliver a strong, cohesive jet of coolant to the grinding or machining area. It is designed to be flexible for setup and be tightened to stay rigid. And, it is designed to reduce costs and increase profits.

The line is made of solid brass. As designed, a single hex line will holds its geometry at 200 psi. The links swivel up to 30 degrees each way, giving the flexibility needed for almost all setups. Adding or removing a link takes less then 20 seconds.

Originally available with hex style tightening only, a new knurled tightening system was introduced in 2010.

It is used on the smaller of the two line sizes. The new knurled system allows for hand tightening with no loss to line geometry. No wrenches or tools are necessary.

Most Popular

RECENTLY ADDED PRODUCTS